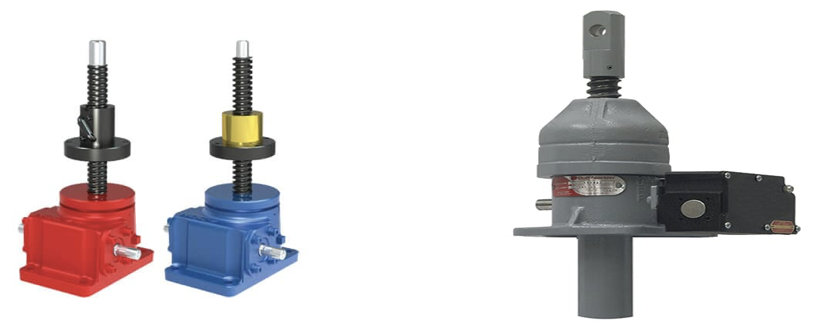

Ball Screw Jacks

Ball Screw Jacks use a ball screw and nut made from hardened alloy steel with hardened bearing balls carrying the load between the nut and screw. This rolling action reduces friction between the nut and the screw, permitting smooth and efficient movement of the load. Because of the greater efficiency and rolling action, the ball screw can operate at higher speeds and increased duty cycle when compared with the Machine Screw Jack.

Worm Gear Machine Screw Jacks

Incorporate an alloy or stainless steel worm which drives a high strength bronze worm gear (drive sleeve). The worm shaft is supported on anti-friction tapered roller bearings with external seals provided to prevent loss of lubrication. The drive sleeve is supported on anti-friction tapered roller or ball thrust bearings.

Comptrol can help you size, design, and provide STEP or AutoCAD drawings for all of your application needs.